As a core hardware device for controlling the automatic closing and positioning of doors (especially glass doors and heavy-duty doors), floor springs are widely used in commercial and public scenarios such as shopping malls, hotels, office buildings, and hospitals, thanks to their strong load-bearing capacity, concealed installation, and stable performance. Their advantages can be elaborated from the dimensions of functionality, adaptability, and user experience:

Core advantages:

Strong Load-Bearing + Stable Door Control, Suitable for Heavy-Duty Doors

The core design of floor springs focuses on “support and control”, and they have distinct advantages especially for heavy-duty doors that traditional door closers cannot adapt to:

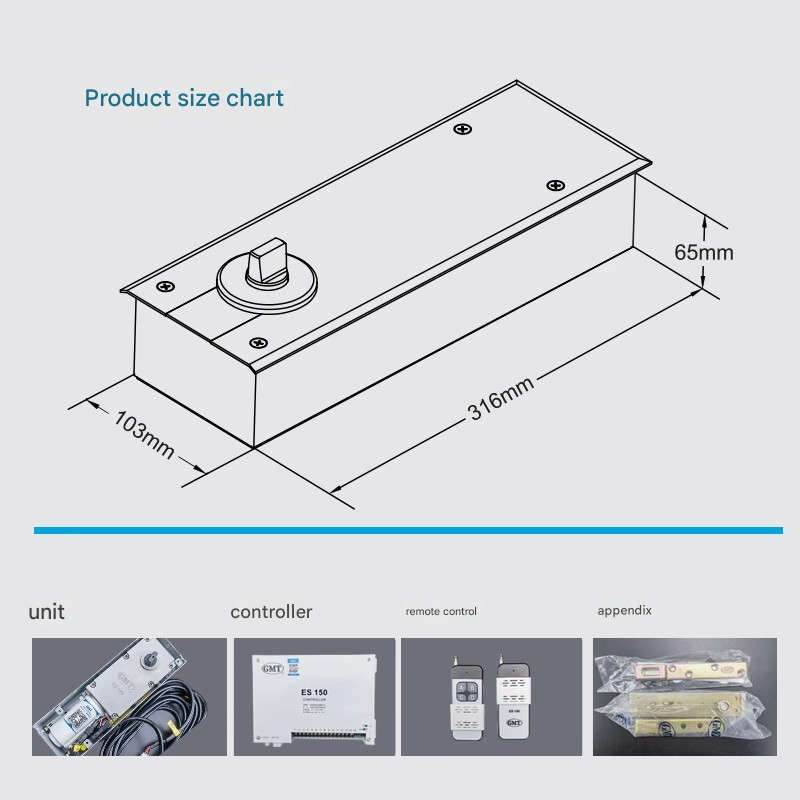

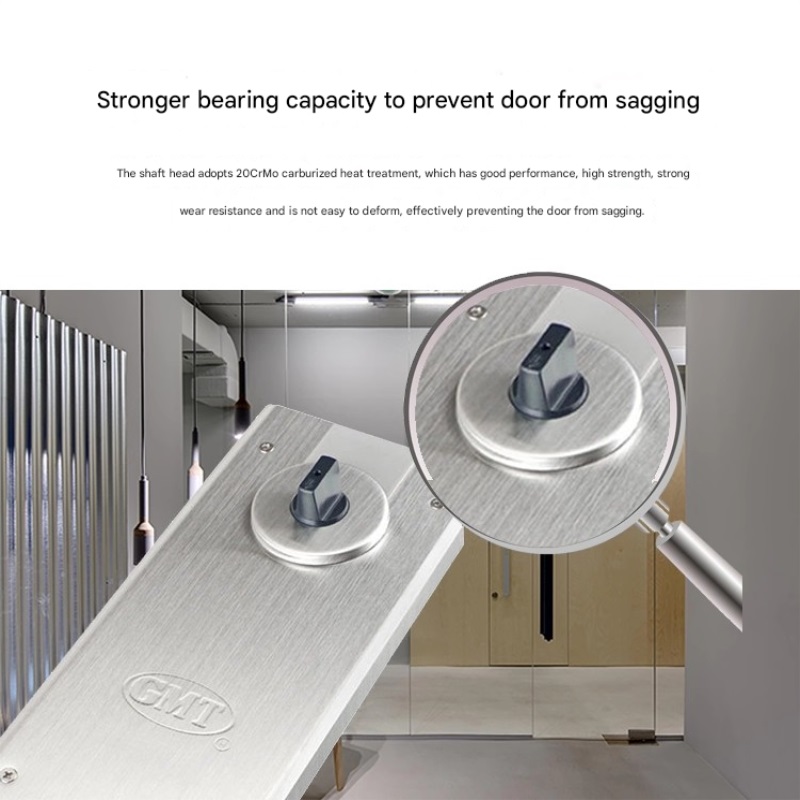

- High load-bearing capacity, compatible with various door typesThe load-bearing range of mainstream floor springs is mostly 60-150kg (some industrial-grade models can reach more than 200kg), which can stably support heavy-duty doors such as glass doors, stainless steel doors, and solid wood composite doors. This prevents doors from tilting or sagging due to insufficient load-bearing after long-term use, solving the “limited load-bearing” pain point of ordinary door closers (mostly suitable for doors weighing less than 30kg).

- Bidirectional automatic door closing with precise controlDifferent from one-way door closers, floor springs enable bidirectional opening and bidirectional automatic door closing (e.g., glass doors can automatically close after being pushed open from both inside and outside). Moreover, they precisely control the door-closing speed through the built-in hydraulic structure—”no resistance in the initial stage of opening and deceleration buffer in the later stage of closing”. This avoids noise or damage caused by the door slamming into the door frame quickly and prevents people (especially in public areas with frequent foot traffic) from being pinched.

- Adjustable positioning to meet scenario needsMost floor springs support the adjustment of “positioning function”. They can be set to “90° positioning” (the door remains fixed when opened to 90°, facilitating the transportation of goods and wheelchair access) or “no positioning” (the door automatically closes immediately after opening). This adapts to different usage scenarios (e.g., 90° positioning is used when goods need to be frequently transported at shopping mall entrances, and no positioning is used when office doors need to be normally closed).

Installation & Appearance: Concealed Installation, Enhancing Space Texture

The “floor-embedded installation” design of floor springs is a key advantage that distinguishes them from other door-closing devices, making them particularly suitable for scenarios with high aesthetic requirements:

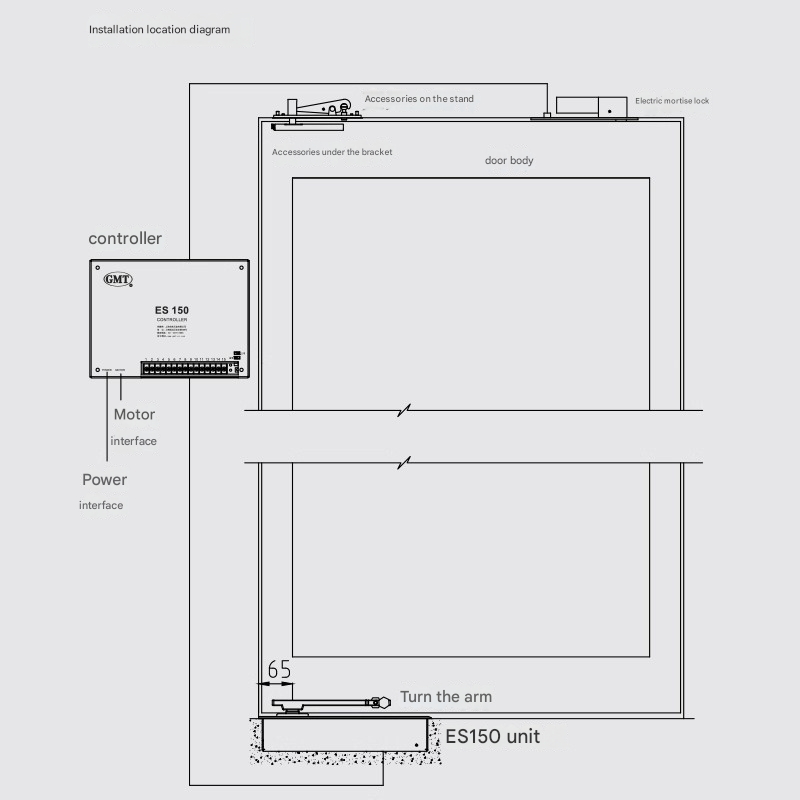

- Concealed installation, without damaging door aestheticsThe main body of the floor spring is embedded in the floor groove, and only connected to the bottom of the door through a rotating shaft. There is no need to install mechanical arms or brackets on the door surface like traditional door closers, which can maximize the integrity and transparency of the door (especially glass doors and minimalist-style doors). This meets the “simple and beautiful” design needs of commercial spaces (such as hotel lobbies and luxury storefronts).

- Space-saving, avoiding collision risksWith no exposed mechanical components, it prevents people (especially children and the elderly) or items (such as carts and suitcases) from being hit by the door closer brackets on the door. At the same time, it reduces the space occupied by the door when it is opened (e.g., narrow corridors and elevator halls), improving traffic safety and space utilization.

Durability & Environmental Adaptability

The structural design of floor springs gives them stronger environmental adaptability and service life, reducing long-term maintenance costs:

- Sturdy structure, wear-resistant and anti-agingCore components (such as hydraulic cylinders, rotating shafts, and springs) are mostly made of corrosion-resistant materials like brass and stainless steel, with excellent sealing performance. They can effectively isolate dust and water vapor (some waterproof models can be used for semi-outdoor doors), reducing rust or jamming of internal components. Under normal use, their service life can reach 5-10 years, which is much longer than that of ordinary door closers made of plastic or thin iron sheets.

- Adaptable to frequent use with strong stabilityDoors in public areas (such as shopping mall entrances and hospital corridors) can be opened thousands of times a day. The hydraulic buffer structure of floor springs can withstand the impact of high-frequency opening and closing, avoiding functional failures caused by repeated stress (such as faster door-closing speed and positioning failure) and ensuring stability during long-term use.

Additional value:

Adapting to Special Doors + Meeting Scenario Needs

In summary, the core value of floor springs lies in their “strong load-bearing capacity, high aesthetics, and good durability”. They are especially suitable for heavy-duty doors, glass doors, and commercial/public scenarios with high requirements for appearance and usage frequency. As a key hardware device that balances “functional needs” and “spatial aesthetics”, floor springs are also important components for improving traffic experience and spatial texture in modern commercial buildings.