The top and bottom pivots (also known as “up and down pivots”) are a type of hardware component used to control the rotation and positioning of a door. The core structure consists of the “top pivot” (installed on the top of the door frame or the door lintel) and the “bottom pivot” (installed on the ground or the bottom of the door). It achieves the opening and closing of the door by supporting at two points. Its functions revolve around “stable support, flexible rotation, and adaptation to special door types”, and it is widely used in scenarios such as hingeless doors, heavy-duty doors, and minimalist-style doors. The specific functions and features can be broken down into the following dimensions:

Core Function

Two-point support, replacing traditional hinges to achieve door rotation

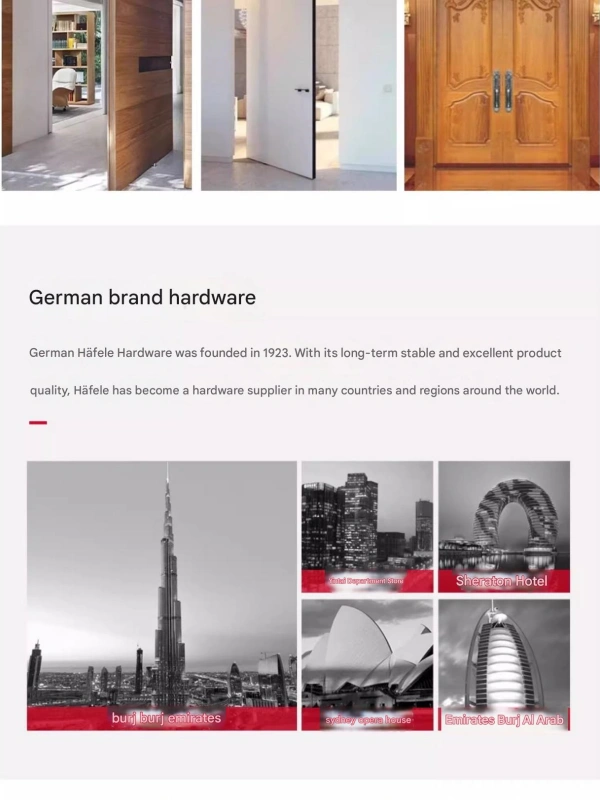

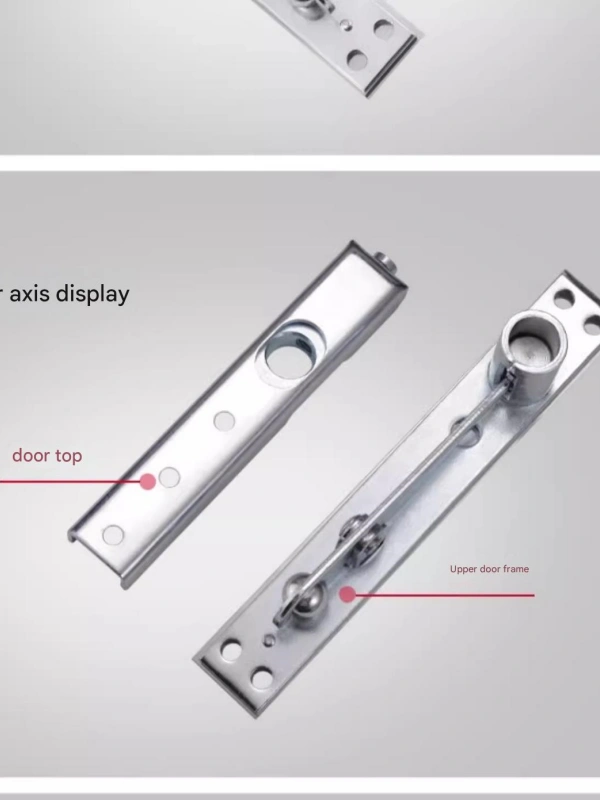

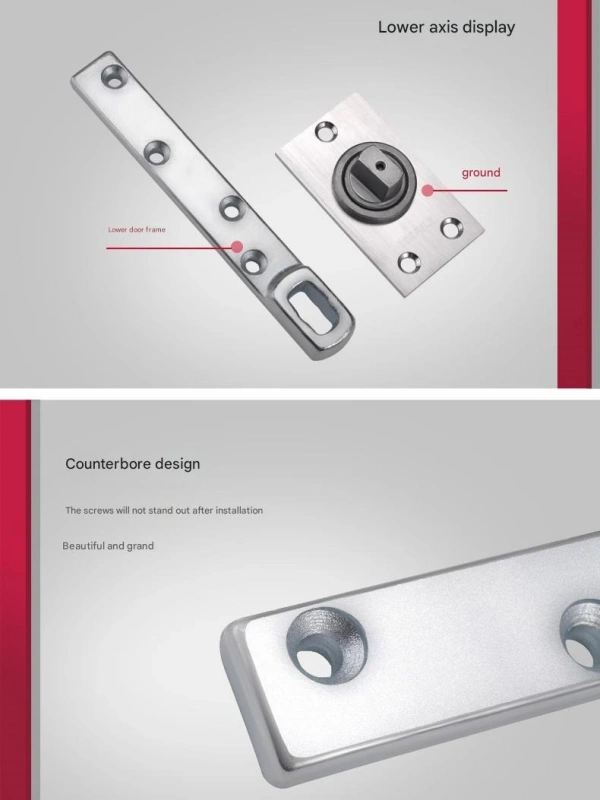

The essence of the top and bottom pivots is “the core hub for door rotation”. Through the symmetrical pivot structure on top and bottom, it replaces the function of traditional side hinges (such as hinges), solving the pain points of traditional hinges that are difficult to adapt to certain scenarios:

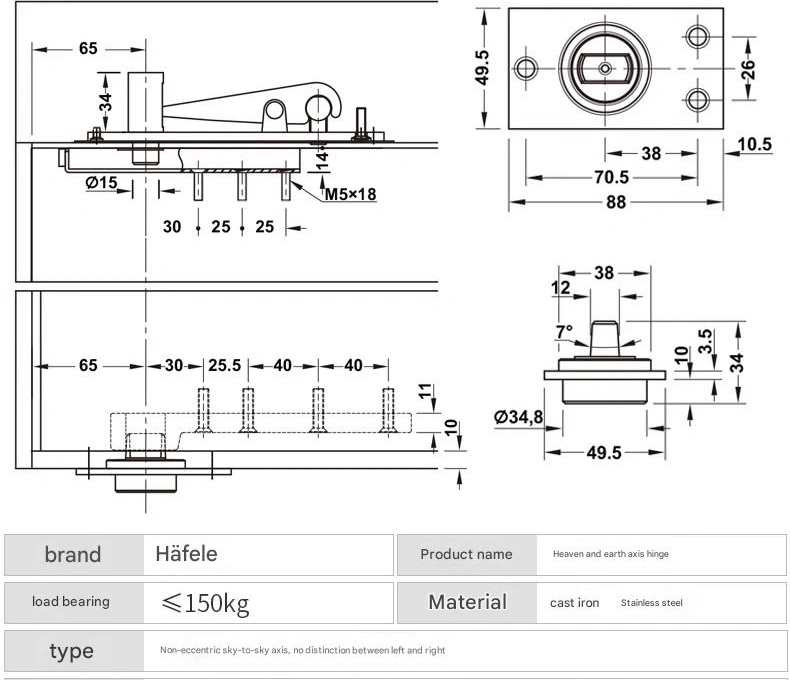

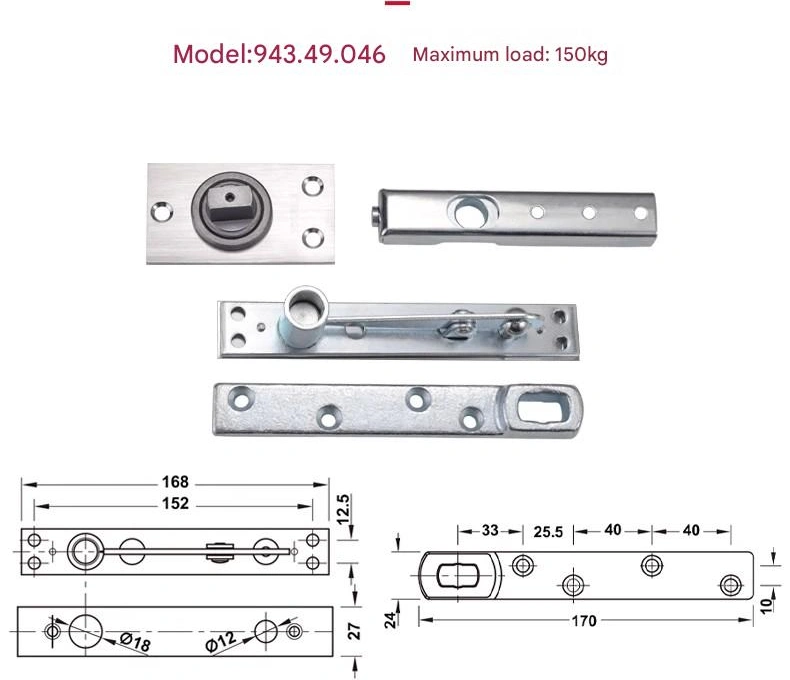

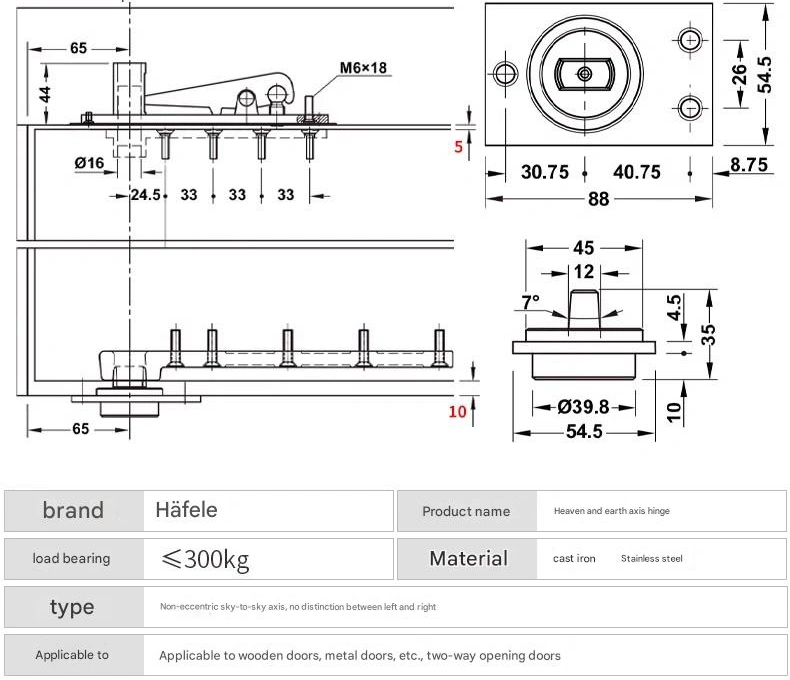

- Stabilize the door and distribute the load pressure: Traditional hinges need to be installed 2-3 times on the side of the door body, concentrating the load on the side, and over time, they can cause the door to tilt or the hinges to loosen (especially for heavy-duty doors); while the top and bottom pivots are supported vertically by two points (the bottom pivot mostly bears the main load), and even for heavy-duty doors weighing over 100kg (such as solid wood doors, copper doors, and glass doors), they can remain stable for a long time, avoiding door sagging or rotation jamming.

- Enable 360° or bidirectional rotation (as per design requirements): Conventional top and bottom pivots can support the door’s bidirectional 180° rotation (such as for public areas with bidirectional door opening), meeting the need for people to pass through from both sides, replacing the bidirectional door opening function of the floor spring;

Special customized models (such as rotating door top and bottom pivots) can achieve 360° continuous rotation, suitable for rotating doors, display areas with irregular doors, etc., providing a stable rotation axis for the door.

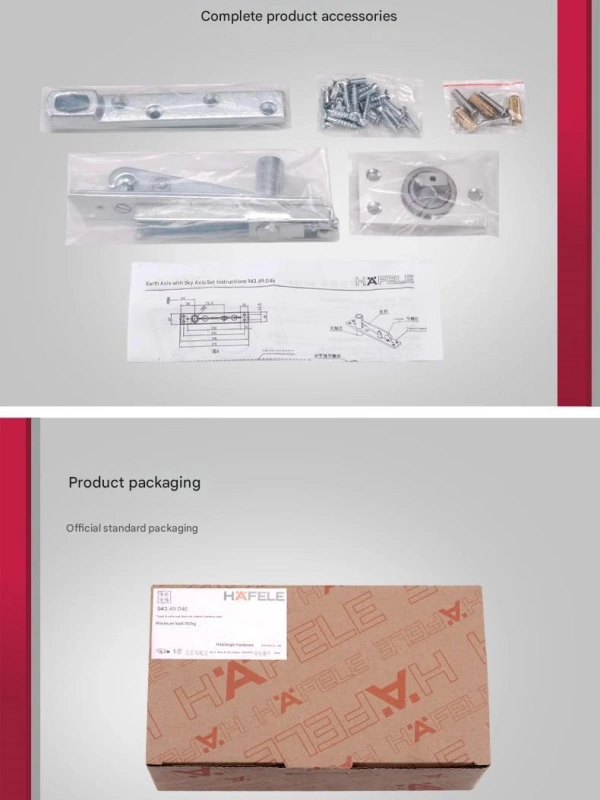

| Category name | Minimum order quantity | Dollar ladder price | unit | Grouping | Core keywords | Country of origin | Outer packaging size | Gross weight KG | Shipped quantity | Estimated delivery time | Packaging method | Sample part |

| HAFELE wooden door heaven and earth axis Rotating hinge | 2 | 50-70 | set | Accessories | Heaven and earth axis | China | 20*20*10cm, | 2.4 | 999 | 10 | cartons | Not supported |

Core Function: Adapt to special door types + optimize space and aesthetics

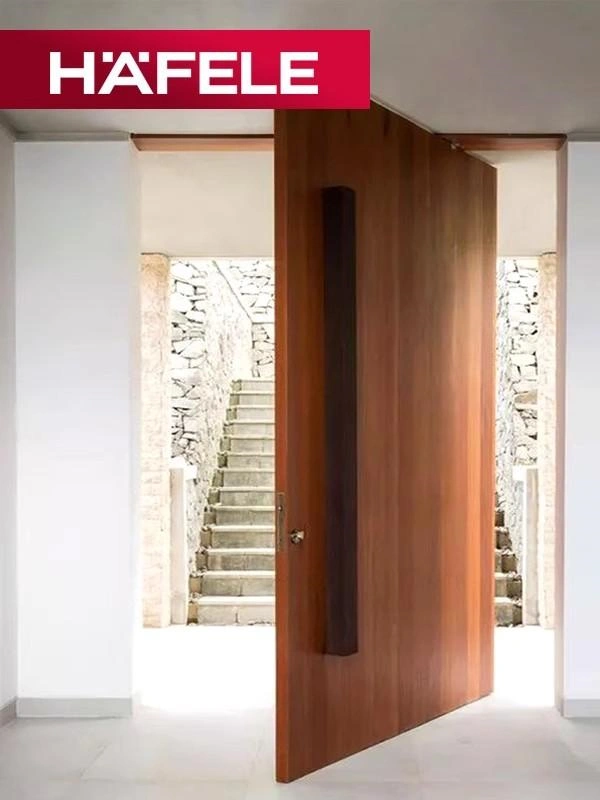

The functional advantages of the top and bottom pivots lie in “adaptability” and “aesthetics”, especially for door types and design requirements that traditional hinges cannot cover:

Adapt to no-frame / minimalist door types, breaking installation limitations

Optimize space utilization, reduce collision hazards

- Adapt to heavy-duty doors and special material door bodies Heavy-duty door compatibility: For heavy doors weighing 50-200kg (such as villa copper doors, hotel solid wood doors, industrial workshop iron doors), the high-load design of the Heavenly Earth Axis (with bottom rotating shafts mostly made of high-strength materials like stainless steel and brass) can stably support them, and has low rotational resistance, making door opening and closing more convenient, avoiding door deformation caused by insufficient load of traditional hinges;

- Special-shaped door compatibility: For curved doors and special-shaped doors (such as triangular doors, irregularly shaped doors), traditional hinges have difficulty finding symmetrical installation points. The Heavenly Earth Axis can adjust the positions of the upper and lower rotating shafts to adapt to the special structure of the door body, ensuring that the rotation axis center is consistent with the center of gravity of the door body, avoiding door shaking.

Additional functions: Enhancing user experience and durability

Wear-Resistant, Suitable for Complex Scenarios

The structural design of floor springs gives them stronger environmental adaptability and service life, reducing long-term maintenance costs:

- Sturdy structure, wear-resistant and anti-agingCore components (such as hydraulic cylinders, rotating shafts, and springs) are mostly made of corrosion-resistant materials like brass and stainless steel, with excellent sealing performance. They can effectively isolate dust and water vapor (some waterproof models can be used for semi-outdoor doors), reducing rust or jamming of internal components. Under normal use, their service life can reach 5-10 years, which is much longer than that of ordinary door closers made of plastic or thin iron sheets.

- Adaptable to frequent use with strong stabilityDoors in public areas (such as shopping mall entrances and hospital corridors) can be opened thousands of times a day. The hydraulic buffer structure of floor springs can withstand the impact of high-frequency opening and closing, avoiding functional failures caused by repeated stress (such as faster door-closing speed and positioning failure) and ensuring stability during long-term use.

Additional value:

Adapting to Special Doors + Meeting Scenario Needs